Team:

Lead Designer

Timeline:

2022

Tools/Processes:

UX/UI Design, Mobile Design

Inspiration and Material Choice

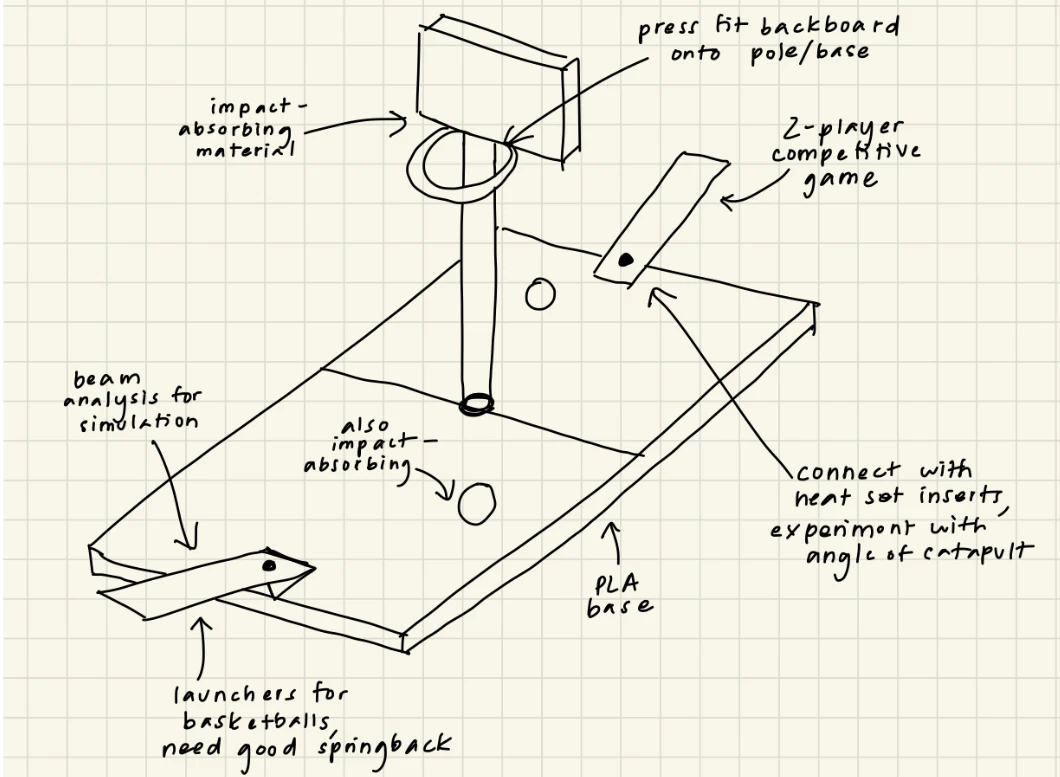

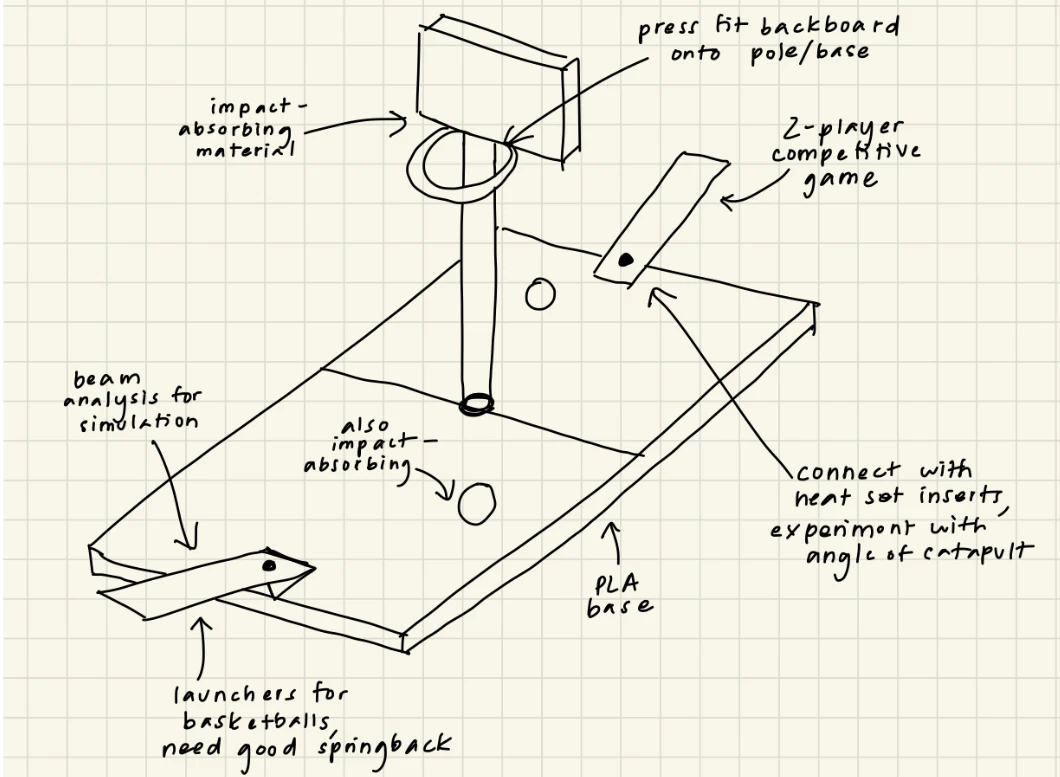

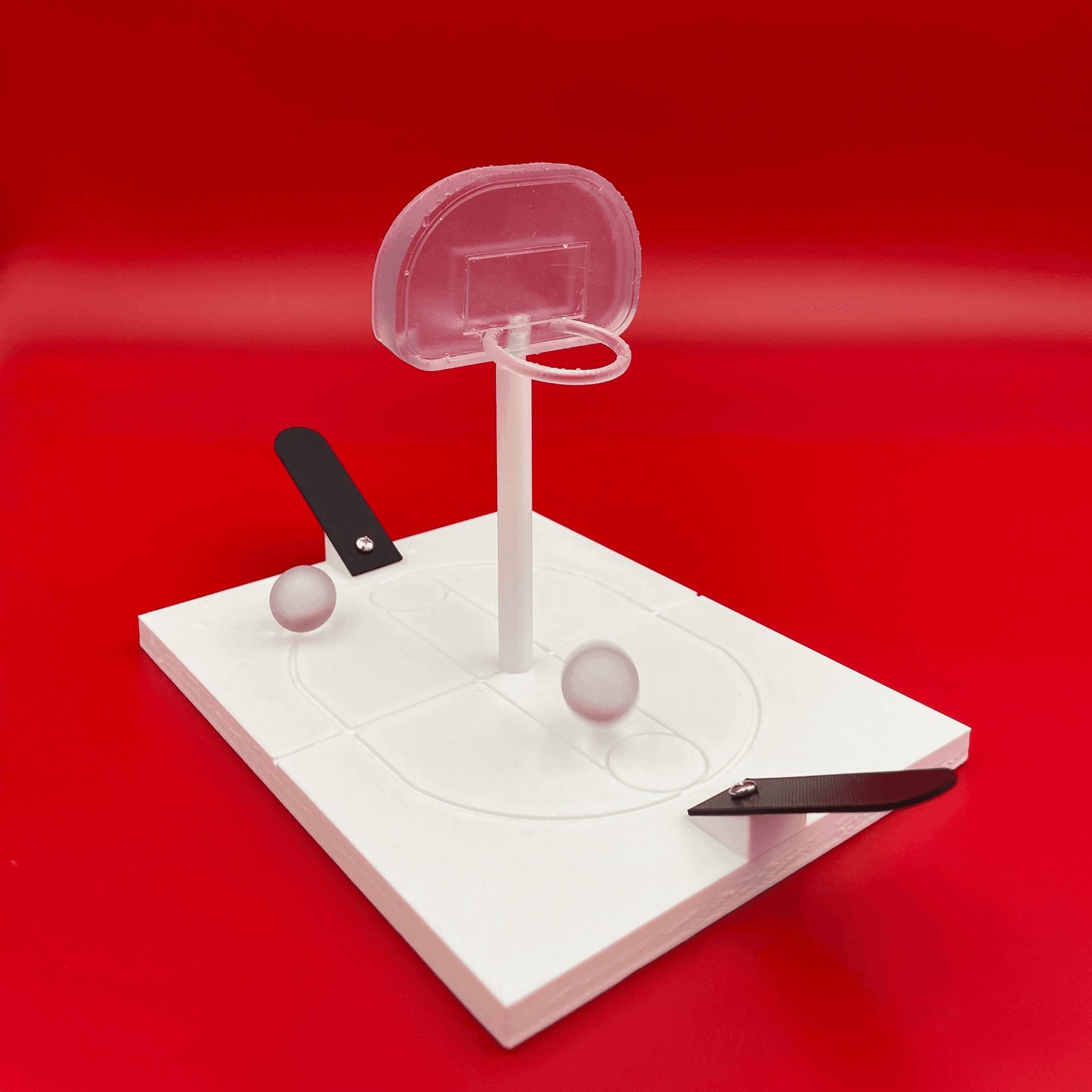

We were inspired by mini basketball games we saw online and the concept of the diving board. The ball could be launched from a mini "diving board" into a basketball hoop. We wanted to create a two-sided board so that the game would be competitive.

For the basketballs and the backboard & hoops, we wanted a material that would effectively absorb force, while not being too jelly-like in terms of physical properties (having a steady form). We decided that Flexible 80A would be more appropriate for our project than to Elastic 50A, since it has a lower elongation at break percentage while having higher tensile strength and tear strength.For the catapults, we wanted a material that was flexible and had springback, while not deforming under stress. We decided that ABS would be more suitable for a more durable and effective launch mechanism, considering how they had greater values for young’s modulus, flexural modulus, and toughness (notched Izod - type of impact test) when compared Tough 2000.We chose PLA for the base so that we could quickly iterate different distances from the catapult to the hoop if needed.